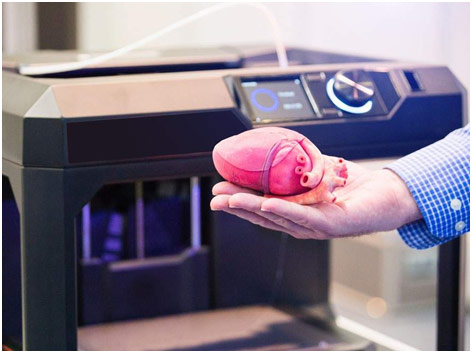

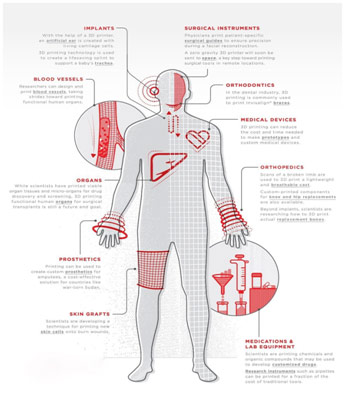

3D printing is the process of using “additive manufacturing” to, from a computer file, make a three-dimensional object, stacking materials layer by layer. The ability to create and then print objects quickly and cheaply translates into plenty of potential medical applications. For instance, 3D printing could be used to create biomaterials that would solve the organ crisis and create less of a fear of rejection. 3D printing could be used to make personalized medical equipment and prescription drugs at a fraction of their current costs. Furthermore, 3D printing could allow students and surgeons to create models on which they could practice standard procedures as well as complex cases prior to doing them on an actual patient. In short, 3D printing offers a means of completely revolutionizing the healthcare experience.

Applications of 3D Printing

Every day, 20 people in the US die waiting for an organ, demonstrating the extent of the organ crisis. The demand for organs like kidneys, livers, hearts, lungs, etc. exceeds the supply; most people on the national transplant list never even receive an organ. Furthermore, even those who do receive organs have to take immunosuppressants for the rest of their lives in order to limit the chance of organ rejection. Even then, these transplanted organs are viable only for a limited timespan with half-lives of organs like kidneys and hearts in the low teens. Therefore, tissues and organs that can be printed on-demand based on the patient’s specific immunological profile offer a way of meeting this massive demand while also drastically reducing the risk of rejection or expiration.

Heart valves, for instance, can be printed to use in valve replacement surgery instead of the tissue ones, often made of bovine pericardium or mechanical ones. The tissue valves only last a decade or two, and mechanical valves have a significant risk of causing a stroke each year. 3D printing a human valve tailor-made for the patient can solve both of those issues. After extensively scanning the anatomy of the patient’s heart, researchers at Cornell actually printed a heart valve by layering stem cells, which served as a “bio-ink.” The stem cells then differentiated and became indistinguishable from native cells, making rejection or expiration unlikely. Similarly, researchers have printed bone scaffolds, which can be extremely useful for treating large fractures, considering that bone grafts are limited in that they are usually taken from the patient, restricting how much can be taken and are not always the correct shape. Thus, patient-specific 3D printed bone scaffolding, made of calcium phosphate so that it may promote healing, eliminates both problems.

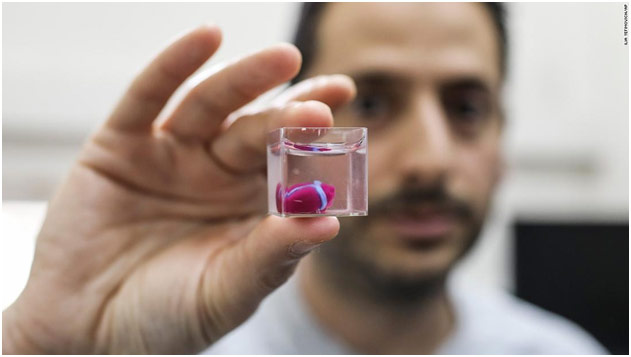

However, perhaps the biggest challenge in 3D printing is creating solid organs like kidneys and livers. Solid organs perform complex biochemical functions that are often difficult to replicate and require a great deal of vasculature. Furthermore, some cells like those of the liver and pancreas cannot grow on their own, so using a scaffold with the patient’s own cells may not work in these cases. Nonetheless, progress is being made. For instance, to solve the two aforementioned problems, researchers have removed the cells from discarded livers to create a skeleton on which they can place stem cells. This way the vasculature remains intact. Furthermore, a group in Israel successfully printed a tiny heart by reversing the patient’s biopsied fatty tissues into stem cells, which then differentiated into cardiac cells. With better scanning mechanisms and more research into printing capillaries, making 3D printed viable solid organs is becoming more of a possibility. Nevertheless, much work still needs to be done to print medically usable solid organs like kidneys, which nine out of ten patients on the US transplant list are waiting for.

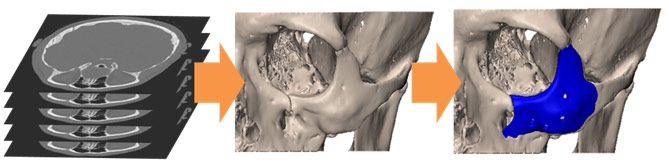

From CT Scan to Specific 3D Printed Implant

3D Printed Tiny Heart

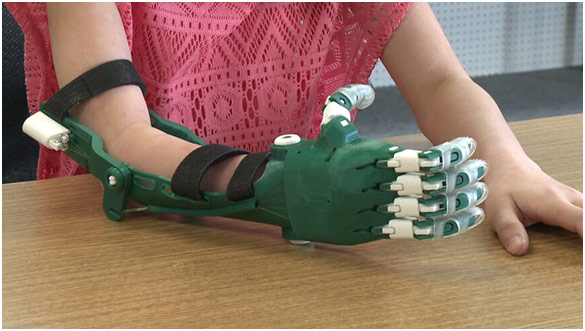

3D printing also affords the opportunity to cheaply and readily produce more personalized medical equipment and medicine. For instance, prosthetic limbs are often mass-produced and quite expensive with “80 percent of the world’s amputees” not having “access to modern prosthetics” per the Medical Futurist. However, 3D printing could slash this cost, making these prosthetics more accessible to patients in developing nations. Furthermore, 3D printing could make it possible to customize the prosthetic to meet the patient’s specific needs. Casts similarly can be designed for the patient’s specific anatomy and have features added to it, such as electrical stimulation, to rehabilitate the immobilized part of the body. Moreover, in 2017, a plastic finger splint was printed aboard the International Space Station, demonstrating how medical equipment can be cheaply produced in remote areas rather than shipping them in. 3D printing has also revolutionized the hearing aid industry by simplifying the manufacturing process and allowing for a more custom “fit” that proves to be more comfortable for the patient. The doctor simply takes a scan of the ear before printing a personalized shell in which the auditory technology can be inserted. 3D printing is changing how medical equipment is produced and who can have access to it.

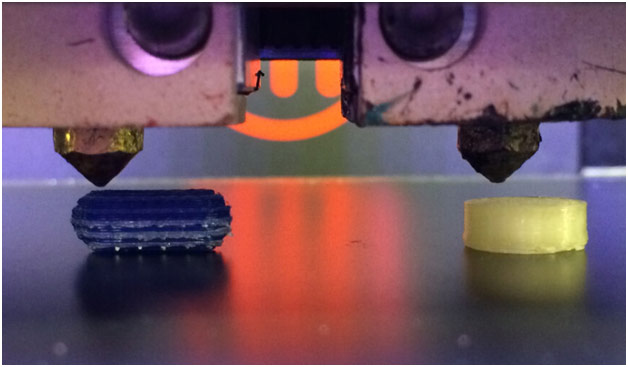

Another light in the future of medicine is the possibility of 3D print prescription drugs. Considering that there are nearly five billion drug prescriptions handed out in the US yearly, there is clearly an enormous demand for medicines. However, the problem of noncompliance where the patient does not take the medicine as directed can sometimes lead to the worsening of the patient’s disease or disorder. As one major contributing factor to noncompliance is the problem of having to take many different pills, 3D printing one specific polypill that includes all of the needed drugs can be very effective at improving adherence. The dream for 3D printing drugs would be to use chemical inks to make the molecules and print the drugs exactly where they are needed. Rare, expensive drugs could be cheaply printed in isolated areas, which might have otherwise not had access to it. Patients could print their personalized drugs in the comfort of their homes, streamlining the entire process. While this future may be far off, the approval of the 3D printed drug Spritam by the FDA could be indicative of a revolution of the entire pharmaceutical industry.

3D Printed Prosthetic Arm

3D Printed Pharmaceuticals

For training and for complicated cases, 3D printing is being used to print models on which students and doctors can practice. Nowadays, extremely detailed life-sized 3D models of the patient’s anatomy can be printed from 2D CT scans prior to the surgery. This can allow surgeons to better visualize the patient’s anatomy and ensure the best possible results. Roadmapping unusual surgeries in the past had to be only based on imaging or practiced on cadavers, which obviously could not represent that specific patient accurately. Therefore, the opportunity to practice with specific 3D printed models represents a novel approach to surgical planning. When Mia Gonzales’s surgeons were contemplating how best to repair her malformed aorta, they created a 3D printed model to better plan out this tricky surgery and ensure that the whole process would go safely. 3D printing has the potential to make previously inoperable cases into operable ones as the surgeon need not enter the OR dubious and unsure. 3D printing simply makes surgeries run smoother. Indeed, a study by Cherkasskiy et al. that compared using a 3D model to not using a 3D model for the planning of a proximal femoral osteotomy surgery saw that the use of the 3D model increased the speed of the surgery and decreased radiation exposure because the fluoroscopy (movable x-ray) was on for less time. Of course, medical students and residents could also learn anatomy and gain valuable experience with these easily printed, realistic models. 3D printing has already revolutionized how the surgery is performed, and it will only continue to do so as 3D printing technology becomes more accessible and widespread.

3D Printed Model Heart for Surgical Planning and Practice

Medical 3D printing is one of the most exciting fronts of the future of medicine as it has the potential to eliminate the organ crisis and revolutionize medical equipment manufacturing, the pharmaceutical industry, and surgical planning, all for the betterment of the patients. As 3D printing becomes more widespread, healthcare will also become more accessible, cutting costs and democratizing medicine. With 3D printing, medicine is changing as we currently know it.

REFERENCES

https://www.youtube.com/watch?v=bX3C201O4MA

https://all3dp.com/2/3d-printed-bones-3-most-promising-projects-of-2018/

http://medicalfuturist.com/3d-printing-in-medicine-and-healthcare/

https://3dprint.com/220137/the-impact-of-3d-printing-on-the-medical-device-industry/

https://www.youtube.com/watch?v=-RkhAP0_ms4

https://health.ucdavis.edu/publish/news/newsroom/13631

https://online.boneandjoint.org.uk/doi/full/10.1302/1863-2548-11-170277

https://www.cnn.com/2015/10/06/health/3d-printed-heart-simulated-organs/index.html

https://www.cnn.com/2019/04/15/health/3d-printed-heart-study/index.html